|

CASERO → Noticias

Noticias

Tradeshows

AFS Metalcasting Congress 2024

CMH MFG Booth #346

April 23 – 25, 2024

Milwaukee, Wisconsin

MORE INFO

Maximize Savings with Remanufactured Machines

Talk to an expert at Metalcasting Congress

Booth 754

Remanufactured 3HS Tilt Pour Machines (6 in Stock)

All wear parts are new!

This low-maintenance, rugged, and dependable Gravity Die Casting Machine stands out with:

- 58,900 lbs. clamping pressure and 4,000 lbs. max mold weight

- Max mold size of 36 x 38 in.

- Twin cushioned tilt cylinders for smooth operation

- Twin ram cylinders for safety, balance, and extra holding pressure

- Hydraulic power units, controls, and accessories must be purchased as new

$62,600 Remanufactured ($82,180 new)

Pinturas Desmoldantes & Protectoras Para Molde Permanente

By John Hall

Click here to View Article.

Download PDF

Merry Christmas and Happy New Year

CMH will be closed in observance of the holidays from Saturday, December 23rd through Monday, January 1st, 2024.

We will reopen on Tuesday, January 2nd, 2024.

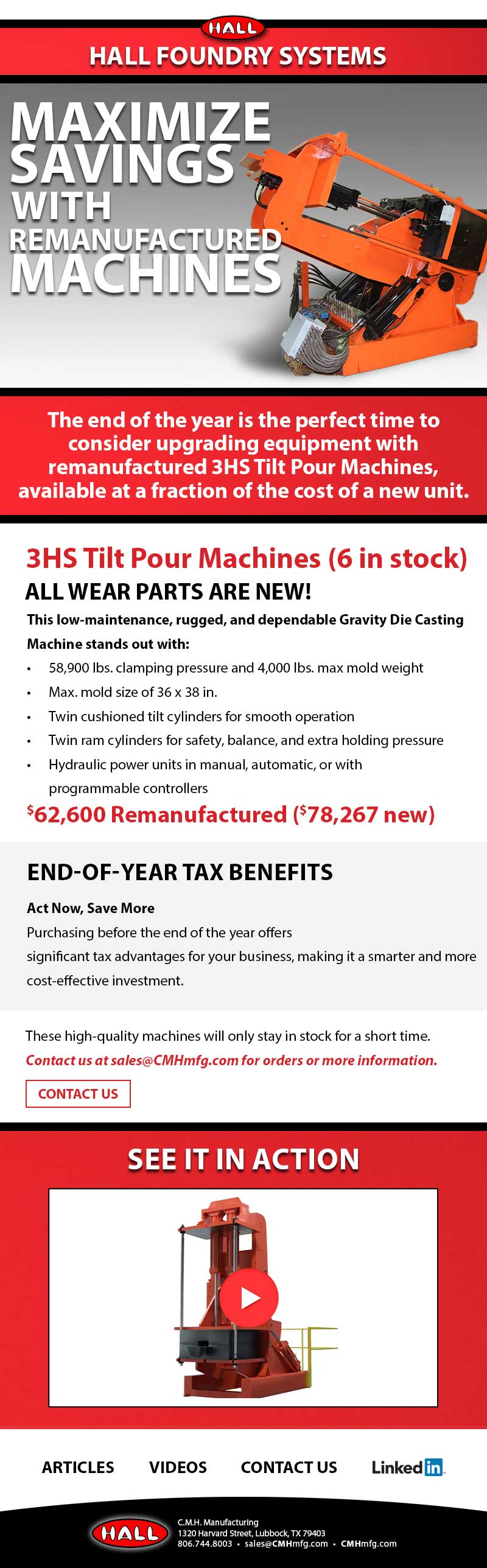

Maximize Savings with Remanufactured Machines

The end of the year is the perfect time to consider upgrading equipment with remanufactured 3HS Tilt Pour Machines, available at a fraction of the cost of a new unit.

3HS Tilt Pour Machines (6 in stock)

All wear parts are new!

This low-maintenance, rugged, and dependable Gravity Die Casting Machine stands out with:

- 58,900 lbs. clamping pressure and 4,000 lbs. max mold weight

- Max mold size of 36 x 38 in.

- Twin cushioned tilt cylinders for smooth operation

- Twin ram cylinders for safety, balance, and extra holding pressure

- Hydraulic Power units in manual, automatic, or with programmable controllers

$62,600 Remanufactured ($78,267 new)

End-of-Year Tax Benefits Act Now, Save More: Purchasing before the end of the year offers significant tax advantages for your business, making it a smarter and more cost-effective investment.

These high-quality machines will only stay in stock for a short time. Contact us at [email protected] for orders or more information.

Learn More

Recognized for their advanced tilt pouring capabilities, these machines minimize turbulence, ensuring consistent molten metal flow into the die cavity. The result?

- Faster cycle times

- Efficient metal usage

- Enhanced aluminum casting quality

With aluminum castings presenting superior hardness, pressure characteristics, and a tight dendrite structure, we offer an edge over other casting methods. Our process facilitates easy integrations, such as sand cores or cast-in ferrous inserts. Having been at the forefront of permanent mold casting technology since 1959, our machines are an amalgamation of decades of experience and cutting-edge technology, driving unparalleled profits and production for businesses.

Learn More

Improve Productivity & Solidification with Water Cooled Dies

Die Cooling System from CMH

- Better Control of Water Cooled Dies

- Reduce Corrosion, Sealing & Hard Water Problems

100 Gallon Stainless Steel Tank

PLC Timer Control stores up to 16 Recipes

Dayton High Booster Pump: 2HP, 3-phase, 208-230/460 voltage, 8.6-8.9/4.5 AMPS

Reverse Osmosis System RO 4-stage 50 gallons water make up per day

AO-15 Heat Exchanger

8-1/4 120v Solenoid Valves with Flow Controls and Flow Meters

Learn More

Equipo de Colado Asistido a Presión con Conciencia Ecológica

By John Hall

Click here to View Article.

Download PDF

Factory Rebuilt Machines In Stock

3HS Tilt Pour Machines (6 in stock)

$62,600 Remanufactured ($78,267 new)

ALL WEAR PARTS ARE NEW!

This low-maintenance, rugged, and dependable Gravity Die Casting Machine stands out with:

- 58,900 lbs. clamping pressure and 4,000 lbs. max mold weight

- Max. mold size of 36 x 38 in.

- Twin cushioned tilt cylinders for smooth operation

- Twin ram cylinders for safety, balance, and extra holding pressure

- Hydraulic power units in manual, automatic, or with programmable controllers

See it in Action

CMH MFG Summer Shutdown

CMH Will Be Closed July 3rd Through July 7th For Our Annual Summer Shutdown. We Will Reopen Monday, July 10th.

If you have a production-related emergency during that time, please call 806.744.8003 or email [email protected]

Experience the New Green Caster Eco at AFS Metalcasting Congress

April 25-27, 2023

Cleveland, OH

Introducing a revolutionary eco-conscious line of pressure-assisted casting machines featuring oil-free, low-energy, and low noise operation. Preview the Green Caster Eco in detailed Virtual Reality.

Cómo Diseñar Moldes para Colada en Molde Permanente

By John Hall

Click here to View Article.

Download PDF

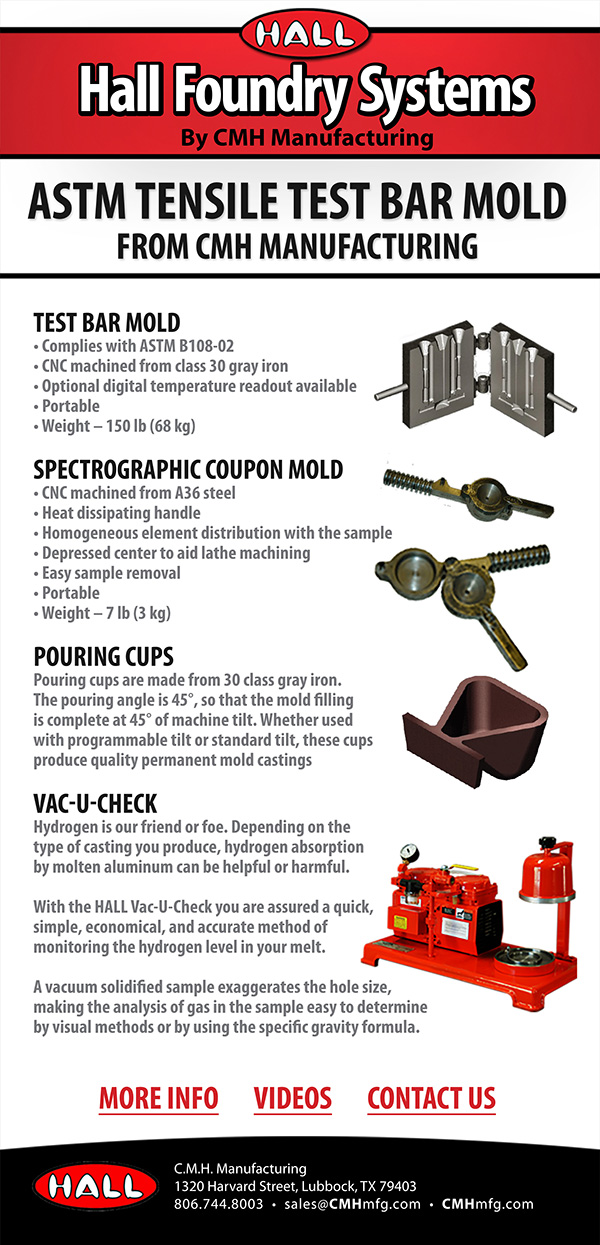

ASTM Tensile Test Bar Mold – from CMH Manufacturing

Test Bar Mold

- Complies with ASTM B108-02

- CNC machined from class 30 gray iron

- Optional digital temperature read-out available

- Portable

- Weight 150 lb (68 kg)

MORE INFO

Spectrographic Coupon Mold

- CNC machined from A36 steel

- Heat dissipating handle

- Homogeneous element distribution within the sample

- Depressed center to aid lathe machining

- Easy sample removal

- Portable

- Weight 7 lb (3 kg)

MORE INFO

Pouring Cups

Pouring cups are made from 30 class gray iron. The pouring angle is 45°, so that the mold filling is complete at 45° of machine tilt. Whether used with programmable tilt or standard tilt, these cups produce quality permanent mold castings.

MORE INFO

Vac-U-Check

Hydrogen is our friend or foe. Depending on the type of casting you produce, hydrogen absorption by molten aluminum can be helpful or harmful.

With the HALL Vac-U-Check you are assured a quick, simple, economical, and accurate method of monitoring the hydrogen level in your melt.

A vacuum solidified sample exaggerates the hole size, making the analysis of gas in the sample easy to determine by visual methods or by using the specific gravity formula.

MORE INFO

Tilt Pour Permanent Mold Casting Guide

Automated hydraulic, electronic and electric operations of all phases of the casting process have dramatically increased production. In the latest edition of Simple Solutions That Work, CMH Manufacturing Co. provides a guide to Tilt Pour Permanent Mold Casting. In this article we discuss the advantages and disadvantages to tilt pour permanent molds. Understand aluminum characteristics and typical casting application

- Aluminum alloy characteristics

- Tilt Pour Process

- Advantages and Disadvantages

Click here to Read the Guide.

CMH Holiday Shut Down!

CMH will be closed in observance of the holidays from Thursday, December 22nd through Friday, December 30th. We will reopen on Monday, January 2nd, 2023.

If you have a production-related emergency during that time, please call 806-744-8003 or email [email protected]

Guía de Colado en Molde Permanente Basculante

By John Hall

Click here to View Article.

Download PDF

Visit CMH at Cast Expo 2022

April 23-26, 2022

Columbus, Ohio, USA

Booth #941

Learn More

Advance your foundry floor into the age of IoT with HALL

Introducing the Hall 6R and Hall smart control

CMH HALL is a leading producer of permanent mold equipment designed for better connectivity between equipment and systems.

We can also help minimize the risks associated with digitization

- Secure Remote Access – to prevent cyber attacks

- Prescriptive Maintenance – to predict operating condition

- Analyze Data from your handheld device – to virtually troubleshoo

John Hall has authored several important articles on IoT, Industrial 4.0 and Cyber Securit

Industria 4.0 y Ciber Seguridad en las Fundiciones

By John Hall

Click here for more information.

Download PDF

CMH MFG Holiday Shutdown!

MH will be closed in observance of the holidays from Friday, December 24th through Friday, December 31st. We will reopen on Monday, January 3rd, 2022.

If you have a production-related emergency during that time, please call 806.744.8003 or email [email protected]

Merry Christmas and Happy New Year

v class="section">

Meet the Hall Family of Robot Friendly Machines

2H Tilt-Pour, 3R Tilt-Pour, 6R Tilt-Pour

SEE THEM IN ACTION! Click here

More Info: Click here

Prevención de Defectos en Fundación de Moldes Permanentes a Través de un Proceso Controlado

By John Hall

Click here for more information.

Download PDF

Principios Colada Por Gravedad (GDC) Utilizando Basculación Reversa

By John Hall

Click here for more information.

Download PDF

La Internet Industrial De Las Cosas Y

La Industria 4.0 En Colada Por Gravedad

By John Hall

Click here for more information.

Download PDF

SEGURIDAD HIDRÁULICA

en Máquinas de Moldeo en Molde Permanente

By John Hall

Click here for more information.

CMH Announces New Robotic Workcell Animations

Defect Prevention in Permanent Mold Casting Through Process Control

By John Hall

Haga click aca.

Effective Die Coating for Maximum Value

In gravity diecasting, coatings can be used to present die wear and control metal solidification rate and direction

By John Hall

Haga click aca.

Artiulo

Parte para fundición por impresión a alta velocidad con la ayuda de un moderno sistema personalizado de fundición, Marzo 2007

Modern Casting, March 2007

Haga click aca.

Anuncios

Jesse Hernandez maneja y supervisa el taller en CMH Manufacturing. El es nuestro empleado mas antiguo, y empezó a trabajar el 21 de Julio de 1983. Cuando empezó a trabajar en CMH, había solo un torno y un hombre trabajando en el taller . Todas las platinas eran taladradas en una prensa para taladrar, y era el único capaz de producir dos por día. Con las mejores en la tecnología una platina puede ser producida en una hora y media. Cuatro hombres comprenden ahora el personal para el taller, ellos operan tornos, fresadoras horizontales, verticales y ambas perforadores de fresado horizontal mediante CNC y centro de torneado mediante CNC con herramientas activas. El taller de metal mecánica esta basado en labrado con precision, con cada parte entre las pocas milésimas de pulgada de precisión. Jesse y su esposa Anna han estado casados por 38 años Ellos tiene tres hijos y tres nietos.

Oportunidades de Venta

CCMH Manufacturing, productor de la linea de equipos de fundición Hall, esta buscando activamente representación en ventas para la expansion Europea. CMH MFG produce equipo de fundición de matriz de vertido por inclinación y ofrece una linea completa de maquinas de fundición diseñadas basadas en el principio de vertido por inclinación Para postular porfavor contacte al correo: [email protected] o llame : 1-806-744-8003.

Reportes informativos

NOTA: Estos reportes informativos requieren Adobe Acrobat Reader. Para bajar una copia gratis haga click aqui.

|

|